Reducing waste and saving money – a dialysis solution sparking interest across Canada

Did you know, just one traditional dialysis system generates 60,879 litres of waste every year – that is equivalent to the average weight of a blue whale. Unity Health Toronto has one of the largest kidney programs in the Greater Toronto Area that provides dialysis treatment for over 275 patients each year. The Clinical Engineering Hemodialysis team at St. Michael’s Hospital, a site of Unity Health, set out to find a solution to reduce the waste from these systems. Within just over a year, they were able to greatly reduce acid waste and saved $54,345.

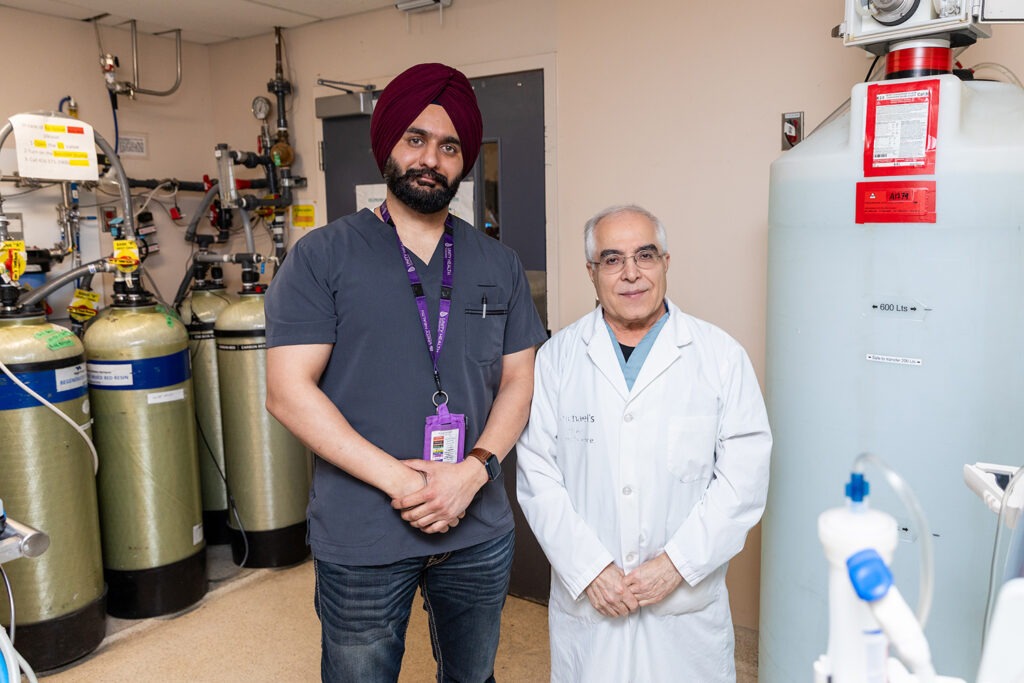

What started as an idea nearly 32 years ago has grown into a transformative project that has had service providers across the country interested in our solution. Hassan Pooya, Dialysis Technologist at St. Michael’s recognized a need when he noticed the amount of unused acid that was being disposed of following dialysis treatments. By developing a system that uses larger drums or barrels of acid concentrate, the team was able to ensure that the acid supply is available for all dialysis stations at all times with less changing out of acid jugs during dialysis care.

Sign up for the Unity Health Toronto newsletter, a monthly update on the latest news, stories, patient voices and research emailed directly to subscribers. If you haven’t subscribed yet, you can do that by clicking here.

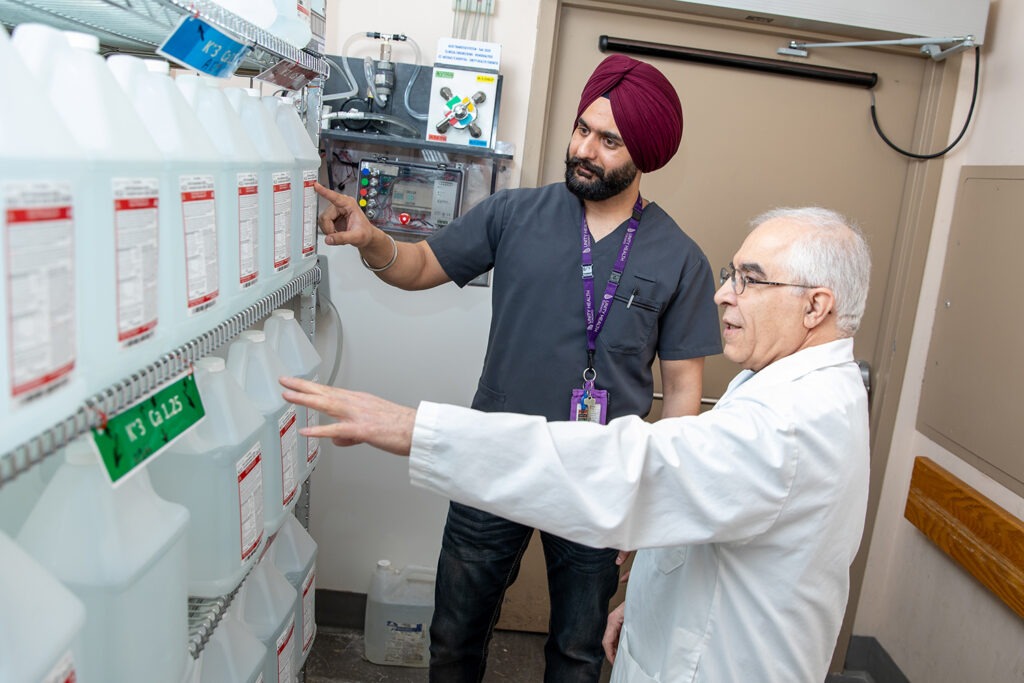

“The new storage system enabled us to have unused acid return back to the storage tanks and recirculate,” said Pooya. “Boxes positioned on top of the system continuously pump the acid concentrate to individual dialysis stations, eliminating waste.”

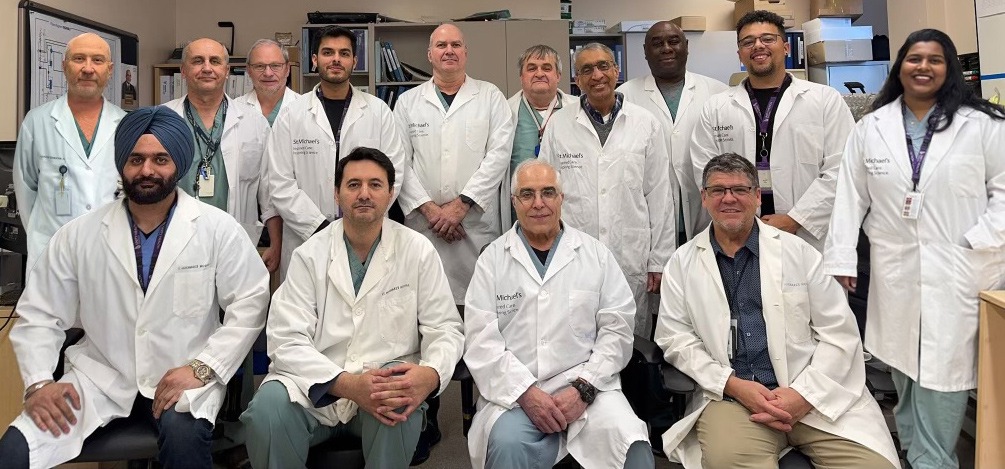

This innovation is unique to St. Michael’s Hospital and has contributed to the hospital’s sustainability efforts. The team has also had the opportunity to present this solution to colleagues across Canada at the Canadian Association of Nephrology Conference, sharing their progress and inspiring other institutions to adopt similar systems.

Over the years, the system has undergone several updates, each one building on the lessons learned from the previous iteration. It started with one acid line and progressed to four acid lines. Along the process, team members Miguel and Juan Carlos also played key roles in advancing the system. The most recent updates earlier this year included the addition of an acid transfer station in February, which further enhanced the system’s efficiency.

The latest system’s design was customized by Singh and Pooya to meet the specific needs of the dialysis unit, ensuring that the operation of the system is helping to create best care experiences for dialysis patients. The new acid transfer system was a pivotal contribution from Sim Singh, Dialysis Technologist at St. Michael’s, who worked tirelessly to refine the process.

According to Singh, “It wasn’t something easy, but we had the motivation to reach the goal.” The Clinical Engineering Hemodialysis team will continue to monitor the system, and is looking forward to creating more beneficial upgrades in the future.

With every update and improvement, they are making a real difference in the lives of those who rely on dialysis.

Editor’s note: An earlier version of this story incorrectly stated a traditional dialysis system generates 59,904 litres of waste, the new system had saved $547,523 and that the idea started 25 years ago. In fact, a traditional dialysis system generates 60,879 litres of waste, the new system saved $54,345 and this started as an idea 32 years ago. This story has been corrected.

By: Caitie Lehman

Photos by Yuri Marakov